Advanced Thermal Treatment (ATT)

![]()

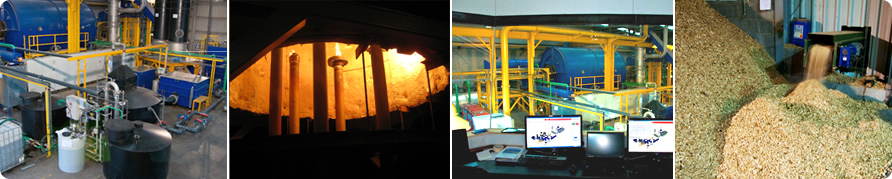

Advanced Thermal Treatment (ATT) is a thermochemical process used to recover energy from waste (EfW). The process involves heating waste in the absence of Oxygen to high temperatures to break it down without direct combustion and produces a useable gas known as syngas. Syngas is composed of gases that include hydrogen, carbon monoxide, methane, and lower molecular weight hydrocarbons, as well as nitrogen and carbon dioxide. The syngas is utilised in gas engines or turbines to generate electricity or heat.

Pyrolysis

![]()

A common form of ATT is pyrolysis. Pyrolysis is a conversion process that uses a diverse range of waste material or biomass in the absence of Oxygen to produce char, oils and syngas. The char is used in a continuous process to produce heat for pure pyrolysis to occur and generate high energy yields.

In contrast to other ATT’s, pure pyrolysis produces a higher calorific value gas leading to increased efficiencies for electricity and heat generation. A thermal process without the use of Oxygen, it has no detectable dioxin emissions making it a better environmental alternative to existing ATT solutions. Pure pyrolysis has increased fuel feedstock diversity compared to conventional ATT’s as the process accepts a wide array of fuel feedstock materials. It thus provides a better alternative for industries seeking a commercially viable waste management solution.

While the concept of pyrolysis has been around for hundreds of years, Stein Pyrolysis introduces a revolutionary pure pyrolysis process that Peter Stein has been developing and refining over the last two decades, surpassing all existing advanced thermal treatments currently available.

Stein Pyrolysis Units are pure pyrolysis, an advanced thermal treatment process which delivers;

- Increased location flexibility

- Optimum energy efficiency

- A higher calorific value syngas

- Enhanced financial returns

- Increased fuel feedstock diversity